Bonding Silicone Rubber To Stainless Steel

Stainless steel adhesives stainless steel glue stainless steel bonding as with other substrates stainless steel adhesives have an advantage over mechanical fasteners as they function well without requiring the part to be altered.

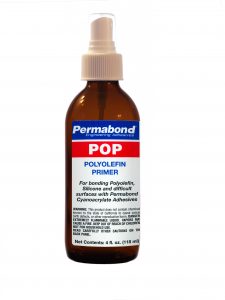

Bonding silicone rubber to stainless steel. Once the metal parts have been prepared it is. Watch the video below on bonding silicone rubber. When working with silicone rubber it is extremely important to understand that polymers are very slow curing. Silicone rubber will almost always need some form of adhesive to enable them to fix to a surface and in many ways can be related to teflon by the way it repels things sticking to it hence the reason teflon is use for frying pan coatings.

Uv curable adhesives bond well to stainless steel providing the second substrate permits uv light to pass through. Chemical treatment of the metal is typically in the form of zinc or iron phosphate for steel acid etching for stainless steel and chromate alodizing or anodizing processes for aluminum. When 100 solids fast bonding and flow over a larger area are the answer 3m hot melt adhesives offer a wide range of open times to meet your assembly needs. Silicone to metal bonding.

Surface preparation and bonding stainless steel. Adhesive bonding of stainless steels 2 theories of adhesion the actual mechanism of adhesive attach ment is not yet fully understood. The bonding of an adhesive to an object or a surface is the sum of a number of mechani cal physical and chemical forces that over lap and influence each other. Silicone rubber will take thirty days or more to fully cure.

No single theory explains adhesion in general. Titanium and stainless steel are often chosen for their strength durability and proven biocompatibility whereas aluminum can be easily processed through molding casting or machining. Metal to glass grades include. Examples range from the bonding of metal housings and turbine blades in aircraft engines and components to sealing pacemakers.

However in most cases the repaired silicone rubber can be put into use immediately. Or see our new stainless steel bonding grades here. The main elements involved in the overmolding processes are the substrate the rubber and the agents. This chemical metal treatment also serves to protect bond integrity.

Often stainless steel can be bonded as received. This stainless steel bonding allows the original strength and aesthetic appeal of the part to remain. Uv610 uv620 uv625 uv670 and uv7141.