Boiler Tube Rolling Procedure

This is time consuming and requires a tremendous amount of skill.

Boiler tube rolling procedure. The boiler is then closed and prepared to fire using all new gaskets. They will take a flare roll expander and roll and flare the tubes to a tight tube joint. If the flaring roll starts to walk under the drum they back the tool out and place the mandrel in the expander tightly and finish the roll. Boiler tube installation new boiler tubes manufactured to meet or exceed specifications are installed rolled beaded and sometimes welded in the hot pass.

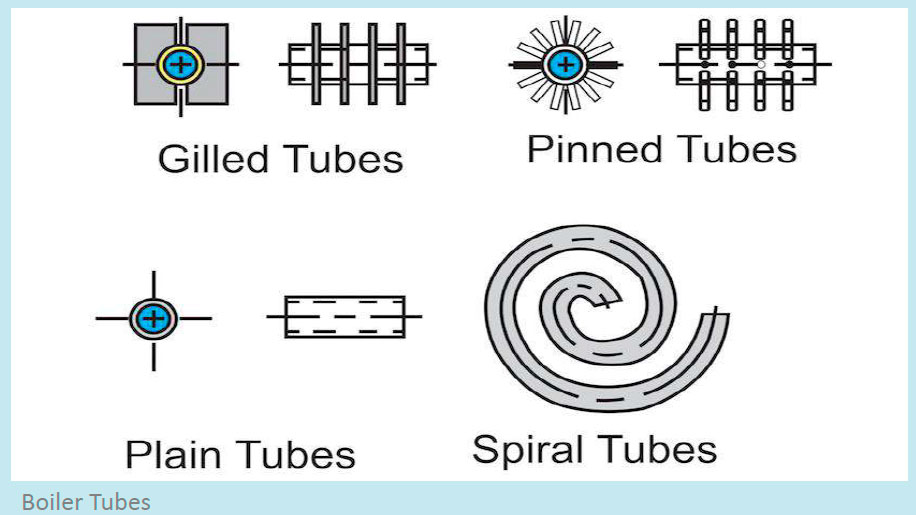

Boiler tubes 12 16 bwg 0 001 5. Tube failures during the initial operation period the normal operation period and after ten to fifteen years operation show different trends. The rolling control is now set and ready to roll the rest of. Good operating and maintenance practice reduces tube failures.

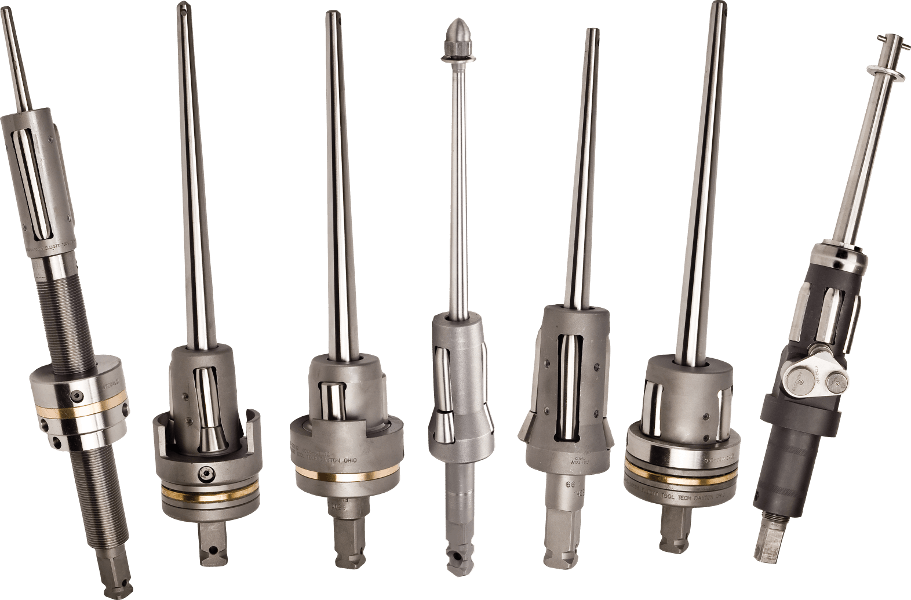

Call 1 718 729 3360 for expert help. Boiler testing qc ib m hydro tests the boiler witnessed by our authorized inspection agency. Mechanical rolling reduces the tube wall by. To assure a proper tube joint the tube wall must.

Tube expanding is the art of reducing a tube wall by compressing the o d. Such as rolling tubes into tube sheets drums ferrules or flanges. Drawing upon a full century of experience and expertise boiler tube company of america bta manufactures replacement pressure boiler components and related auxiliary industrial boiler parts for all sizes and styles of boilers regardless of original oem. The use of the torque control system will ensure the uniform tightness of all tubes.

Reroll all test tubes that were under size. There are manufacturers who feel that rolling the tube with a flare roll expander only is the best procedure. Of the tube against a fixed container. To ensure the best tool life and the highest quality tube to tube sheet contact.

Welding procedures cleaning procedures step sequence for tube to tubesheet joint completion including welding special closefit per tema table rcb 7 41 inspection and test plan like quality plans inspection and test plans can vary with heat exchanger types but major steps can be seen in figure 6. There are twenty two primary reasons for tube failures in a boiler which can be classified under six major groups. They can be analyzed and corrective and preventive action can taken. To roll tubes into tubesheets thicker than 2 you must step roll.