Boiler Blowdown Water Hardness

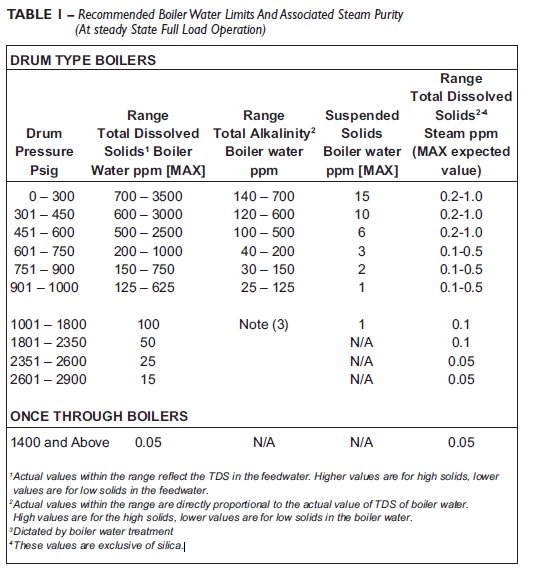

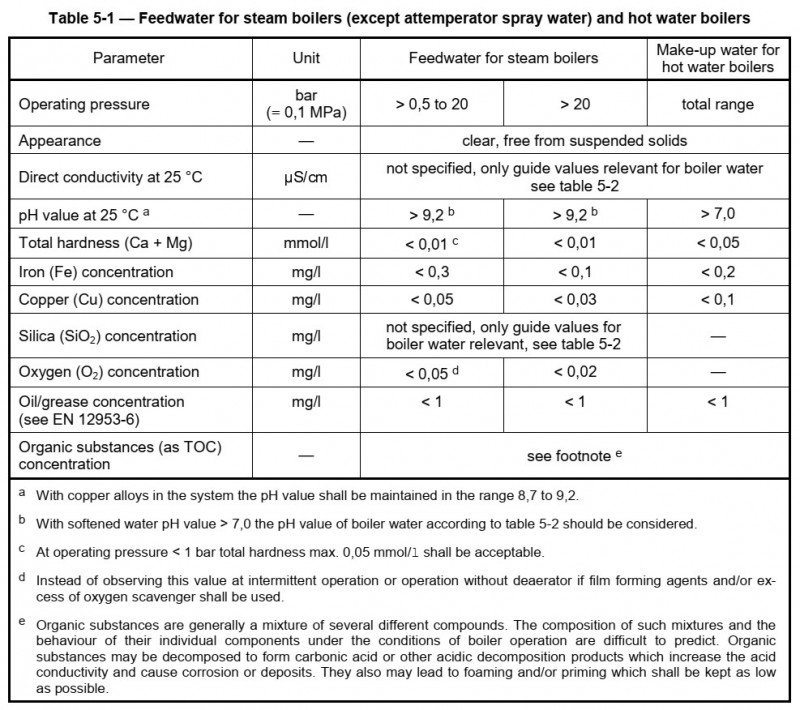

Maximum allowable water impurities.

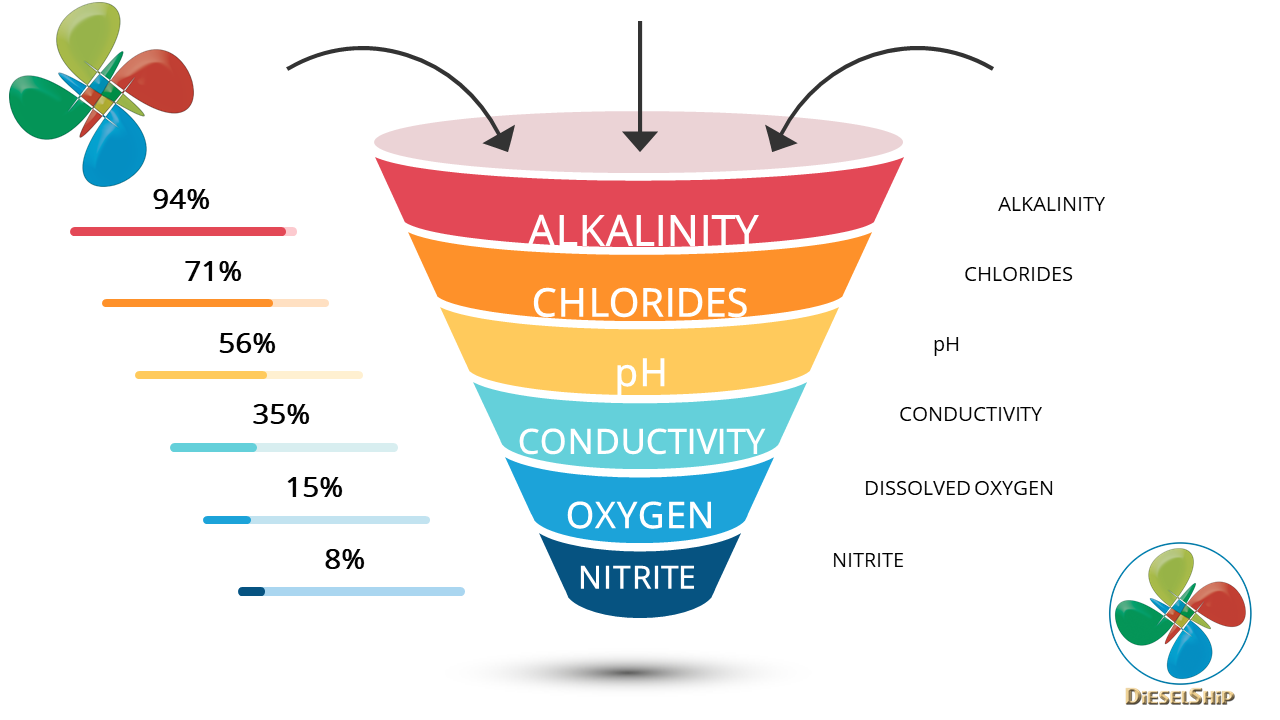

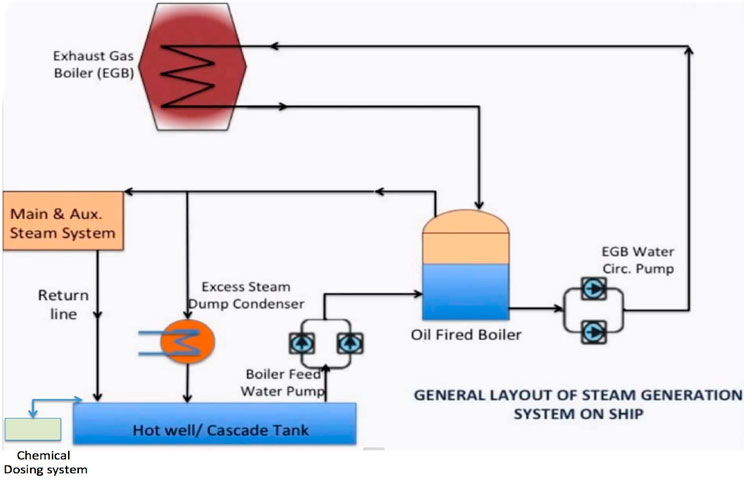

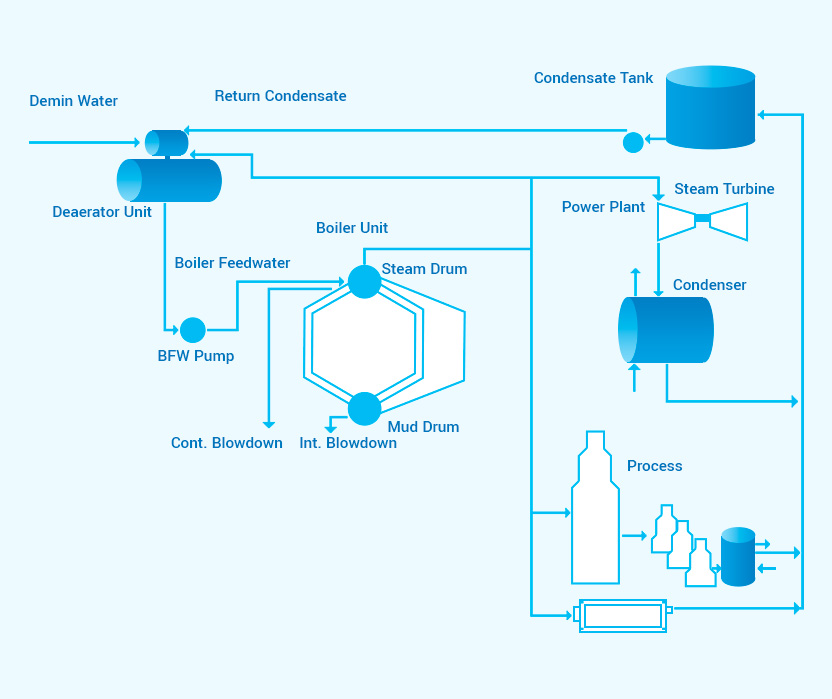

Boiler blowdown water hardness. My doubt is what should be the hardness of blowdown water generaly we are not measuring it only we maintening the feed water hardness below 2ppm we are having softner not dm plant. Its purpose is to control boiler water parameters within prescribed limits to minimize scale corrosion carryover and other specific problems. Blowdown is also used to remove suspended solids present in the system. Before boiler blowdown can be discussed and understood it is necessary to establish a definition of water along with its impurities and associated terms such as hardness ph etc.

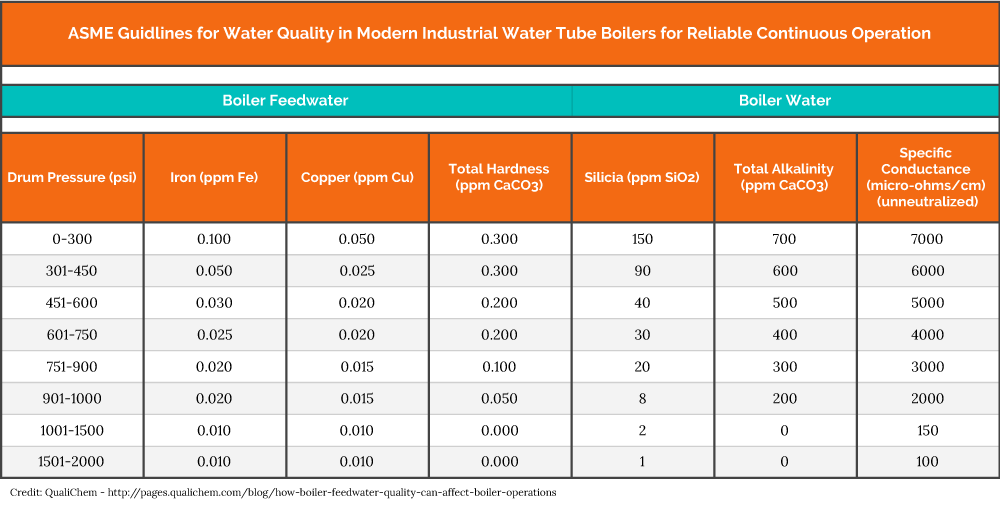

Asme guidelines for water quality in watertube boilers. A low pressure fire tube boiler can usually tolerate high feed water hardness with proper treatment while virtually all impurities must be removed from water used in some modern high pressure boilers. Total hardness should not. In boilers the hardness of the water can cause the formation of scale and sludge or mud.

Water area manager and ray gesling b s m e. Hello everybody here i have doubt on the boiler blow down water. It is essential to life it is used for transportation and it stores energy. Blowdown in boiler usually water which is fed to the boiler contains high total dissolved solids tds content as well as other dissolved and undissolved solids in it.

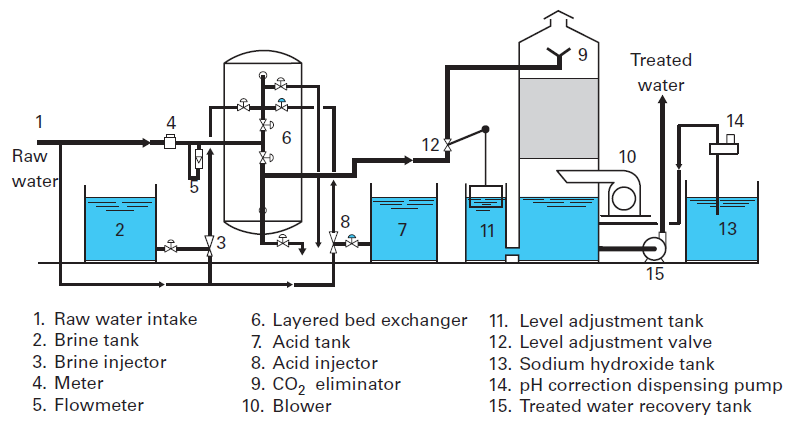

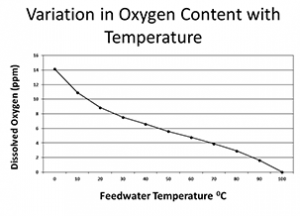

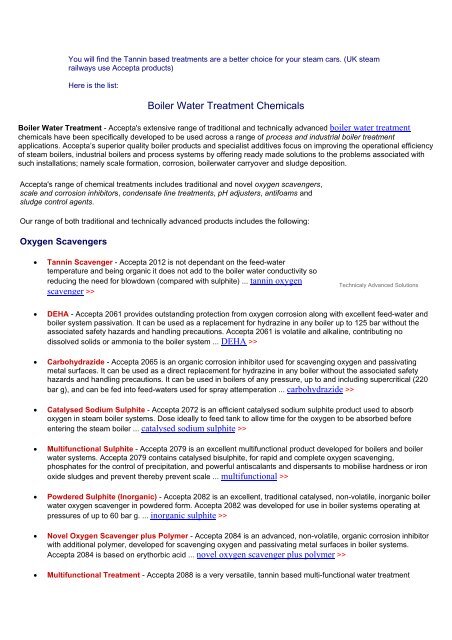

Feed water purity requirements therefore can vary widely. Blowdown in boiler definition. Most boiler systems have sodium zeolite softened or demineralized makeup water. On heating water or converting water to steam these dissolved solids do not evaporate and gets separated from water or steam and settled at the bottom of the shell.

Describe a recent case study in which a water technologist and pharmaceutical plant engineer teamed up to master and manage downstream hardness upset in a boiler system. A continuous blowdown system use a calibrated valve and a blowdown tap near the boiler water surface. The hardness of water is caused by calcium and magnesium ions which will vary greatly throughout the country depending on the source of the water. The hardness must be removed in the makeup water to the return system.

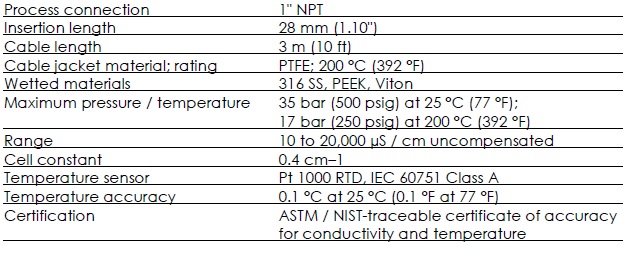

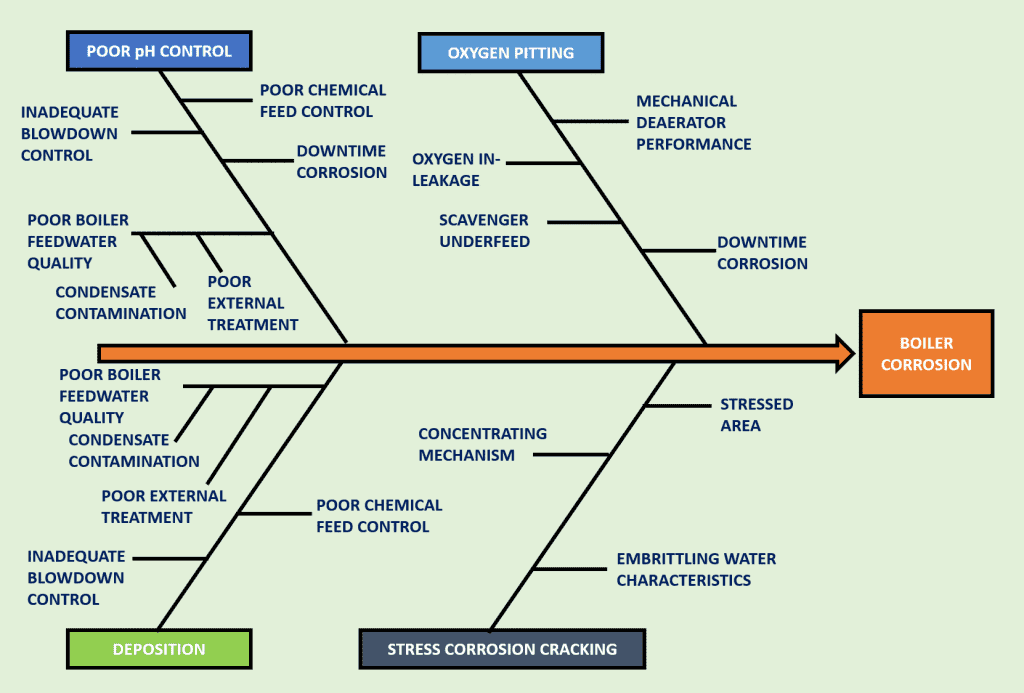

Therefore good internal boiler water treatment programs are necessary. Water is continuously taken from the top of the boiler at a predetermined rate. Feedwater hardness usually ranges from 0 01 to 2 0 ppm but even water of this purity does not provide deposit free operation. Obviously the conditions are very different from those of the sample obtained via the sample cooler which will be cooled and subsequently neutralised ph 7.

We are maintaining only tds ph sulphides of boiler blow down water. Water is the most important raw material on earth.