Blindside Concrete Wall Forming

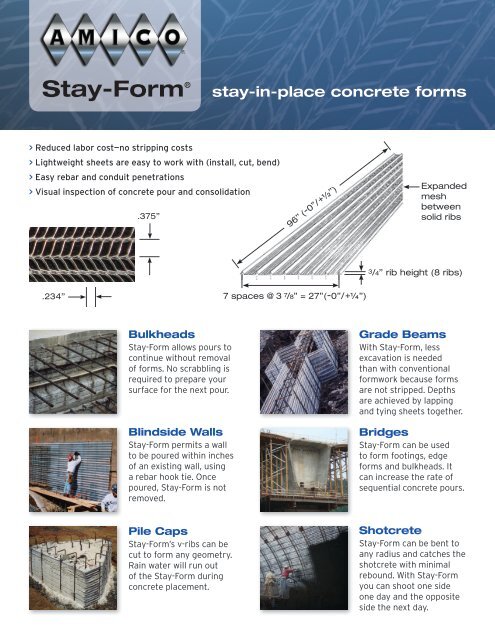

A number of specialty accessories are available to make the job easier and prevent bulging walls.

Blindside concrete wall forming. By utilizing stay form with rebar studs hook ties and a modular form system a one sided form or blindside wall can be constructed. Here workers are removing concrete and adding braces to stop the form from moving. Even on this short wall the concrete pressure was sufficient to move the form. Such situations require the use of one sided forms and special attention to bracing or tying.

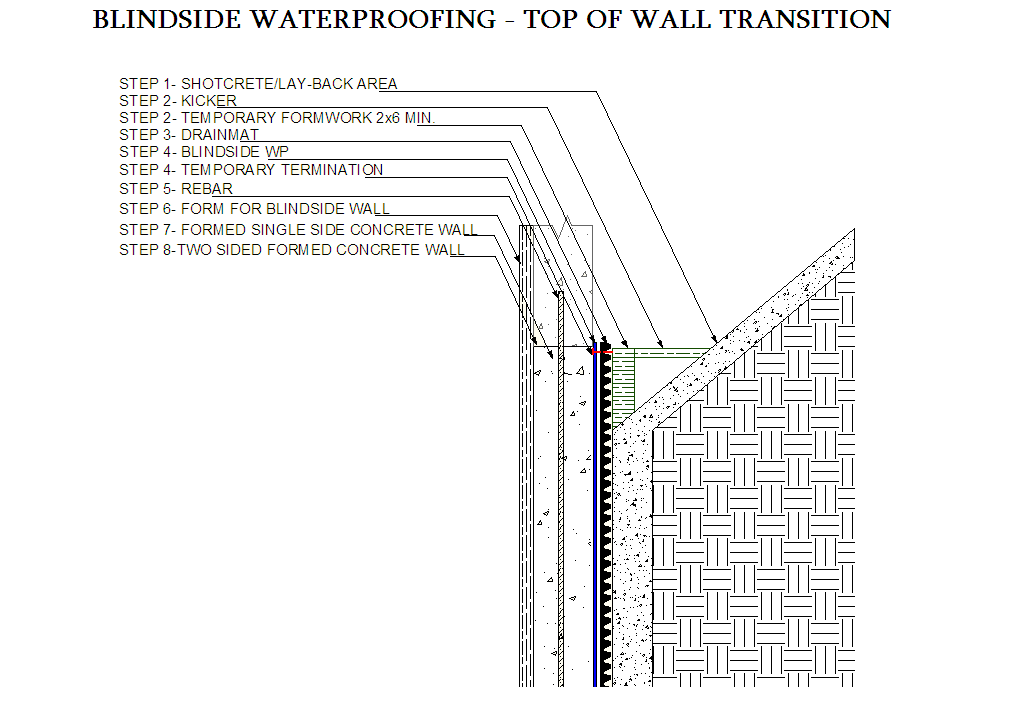

Voltex waterproofing was applied to the stay form. Without ties one sided wall forming can lead to bulges and blow outs. If you do not have the luxury or room to strip formwork stay form is the right product for the job. Blind side and one sided forming by bruce a.

Steel dog offers the most comprehensive line of one sided and blind side forming hardware. Note the slits placed in the stay form to allow the installation of the hook tie. Tie almost any handset form system to almost any existing wall or structure. However some of the systems require the use of a sill 1 to position and connect walers to formwork as an assembly.

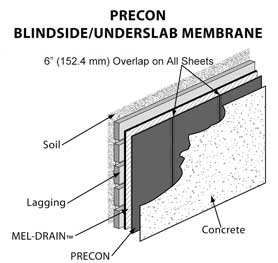

A frame steel channel waler. According to kidder parker architects and builders handbook the first blindside membranes were multiple layers of burlap or felt swabbed with hot pitch or asphalt applied over the drainage tile and covered with bricks. Fiberglass form ties effortless installation no rust heavy duty. Manufacturers provide specialty form accessories.

This is a view of the backwall of the wall panel prior to the concrete pour. These one sided wall forming components are designed to fit the 5 or 8 walers used with most forming systems. New concrete wall sometimes must be placed against existing concrete walls earth banks or shoring. Concrete was a rare material at that time but had already started to make its way into the foundation wall.

When forming against a preexisting foundation wall if space allows there is a possibility that two sided forms can be used. If the waler assembly and the forms are lifted separately a waler connection positive connection is not necessary. The assembled ganged formed blind side wall panel before it was lifted to a vertical position. At this point one can be reasonably assured that the concrete has been properly consolidated.

The blind side or the back side between the old and new wall can be formed with instruments similar to those used for one sided forming. Even with blind side wall applications the vibrator operator can look down the backside of the stay form and see when the concrete paste blossoms through the form to cover the face of the form. When a contractor has to form a concrete wall within a few inches of an existing structure stay form is an excellent product.